A Coop and Run to House Six Chickens

Raising backyard chickens is more popular than ever. It's an enjoyable hobby that pays off in fertilizer, pest control, companionship and, of course, fresh eggs. Raising chickens starts with the right housing, but finding a coop that is appropriate for the flock, easy to maintain and still looks good in the yard can be a challenge.

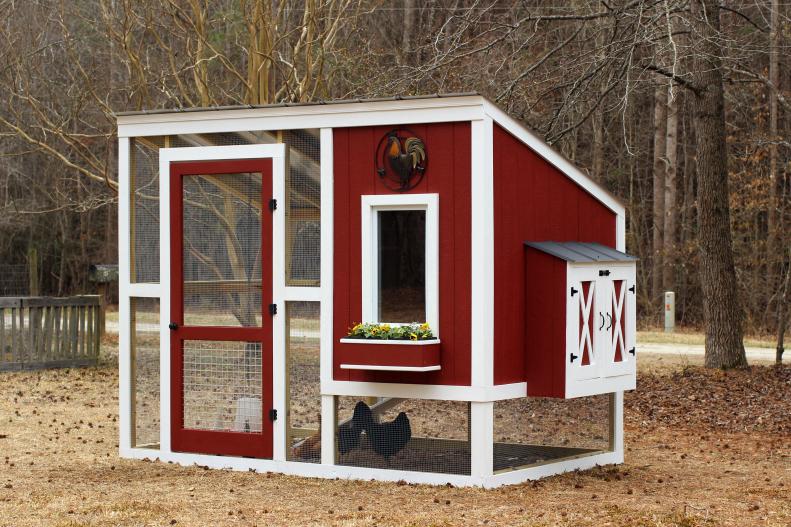

HGTV has got you covered with these plans for a DIY coop and enclosed run with a small footprint to fit any yard. This raised-coop enclosure offers room for six chickens, a walk-in run, built-in storage, an observation window, external egg collection and the simple design only takes up a 6-foot by 10-foot area.

Download our free, detailed chicken coop plans and explore this gallery to see this efficient design customized four ways, including a basic coop, elegant and rustic modifications and a plan to convert this sturdy structure into an attractive and spacious garden shed should a backyard chicken coop no longer be necessary.