1 / 25

Photo: Rachael Jones.

From:

HGTV Handmade.

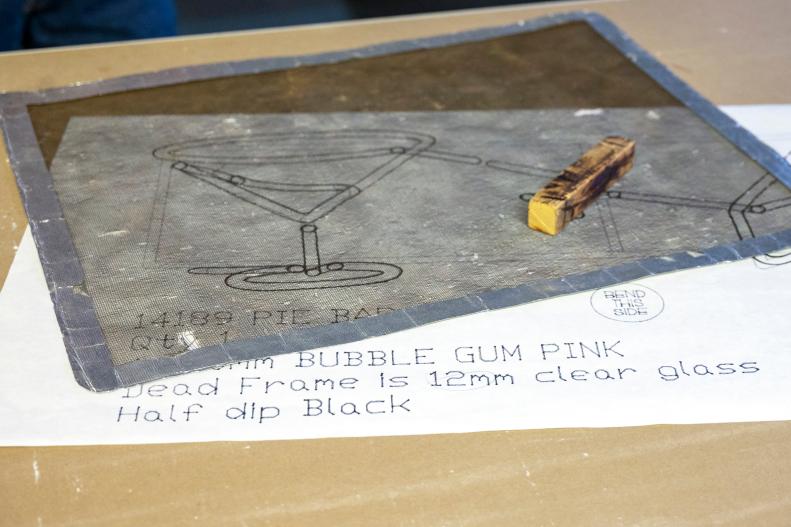

Heart of Glass

Will Kirtley, Seattle artist and lead glass bender at custom sign shop Western Neon, is the man behind many of the Emerald City’s brightly colored beacons. Best known for its gloomy, gray days and alt rock vibe, the city is considered to be the world's epicenter for glass art. Learn how Will blends handcrafted art with science to create a one-of-a-kind neon sign, and the journey he took to reach this level of artistry.